Composite Wrapping for Lightweight Strength

Industries with critical applications such as aerospace and automotive require lightweight cylinders capable of withstanding intense pressure. Composite overwrapped pressure vessels (COPVs) are the ideal solution. We’re experts at manufacturing COPVs with significantly higher burst pressures compared to cylinders made only of aluminum.

We have unique capabilities and experience manufacturing these lightweight cylinders, such as COPVs certified for 4,500 PSI and compliant with DOT and ISO standards for Type 3 hydrogen storage. We also make the lightest paintball cylinder in the world – weighing 1.5 pound with a 4,500 PSI service level.

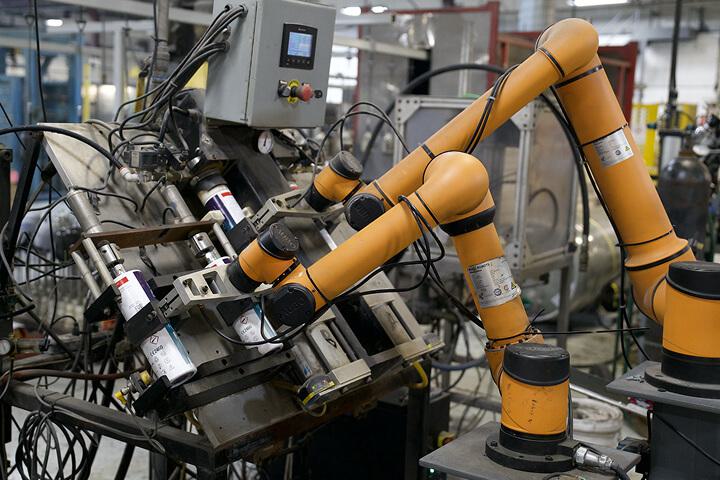

All processes at Precision Impacts are performed in-house, from engineering to finishing. We work with a range of materials, including specialized UV coatings that give the COPV a high-end finish (even glow in the dark!).