Custom Solutions

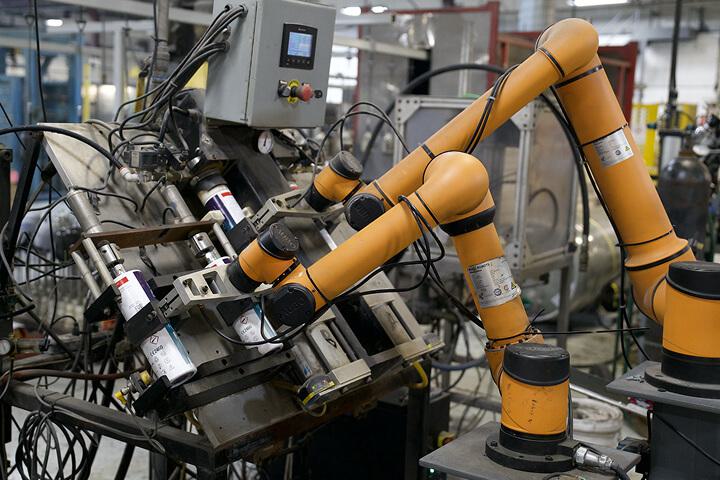

Realize your aluminum possibilities with our customized end-to-end manufacturing services. Each production line is set up for your specific cylinder and designed to automate as much of the process as possible. Not only do we manufacture cylinders we also fill and distribute product. Our vertical integration allows Precision Impacts to deliver unmatched value.

After the impact extrusion comes heat treating to achieve the material’s maximum mechanical strength. Depending on your application, we machine your cylinder using turning, milling or drilling to create ports, drill holes, or perform other required manufacturing services. Food grade and medical grade cleaning equipment ensure no impurities remain within the cylinder.

Next, your cylinders move to finishing operations, where your product is customized. Painting, silk screening, shrink sleeve and labeling, as well as laser etching are all completed in-house. We can add barcodes for traceability or QR codes for additional product information.

Assembly, filling, packaging and national or international distribution round out our manufacturing services.